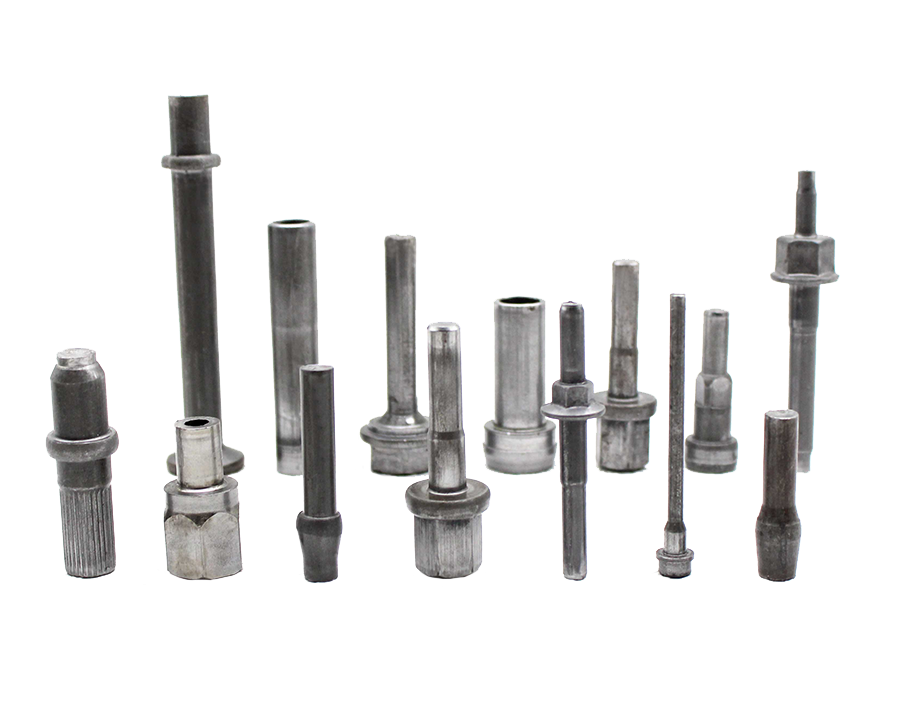

Multi-station cold heading machines mainly produce fasteners and special-shaped parts. And cold forged parts are indispensable basic mechanical parts for industrial production and are widely used in automobiles, railways, aerospace, electricity, machinery, electrical appliances, electronics, military industry, ships, petrochemicals, construction and other fields. Cold heading forming equipment belongs to the metal forming machine tools in the machine tool industry. It mainly uses discs or bars as raw materials and uses cold heading forming technology to continuously produce fasteners such as bolts, nuts, pins, steel balls, rollers, and special-shaped parts such as complex bevel gear shafts, ball pins, spark plugs, brake shafts, rotating shafts, socket wrenches, hub screws, universal bearings, hardware, etc.

|

|

The material selection of parts is the best, the heat treatment process is the best, and the design overload capacity of the machine is relatively large, which can cope with temporary or small batch over-machine models.

The machine body adopts high-quality castings made of HT300 material with small thermal deformation, and the service life and thermal deformation are small, thus achieving the same precision effect of cold machine and hot machine.

The assembly clearance of sliding parts reaches 0.03-0.05 wire in oil-free state, and the sliding fit within 0.01 in oil injection production state

It is suitable for the concentricity requirements of complex parts, and the concentricity of parts can reach within 0.05.