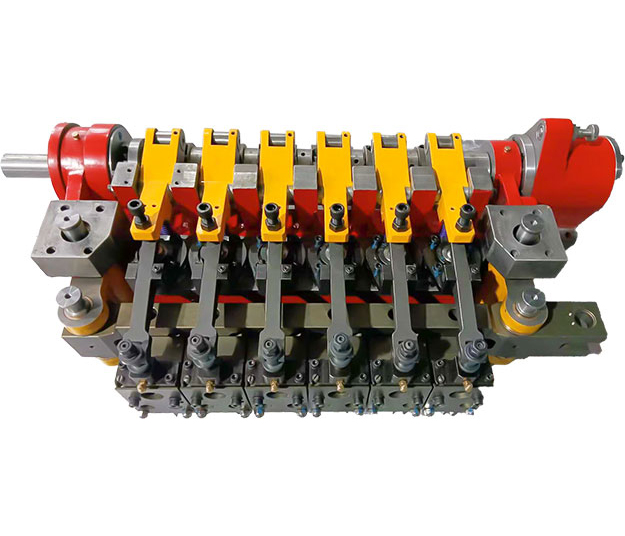

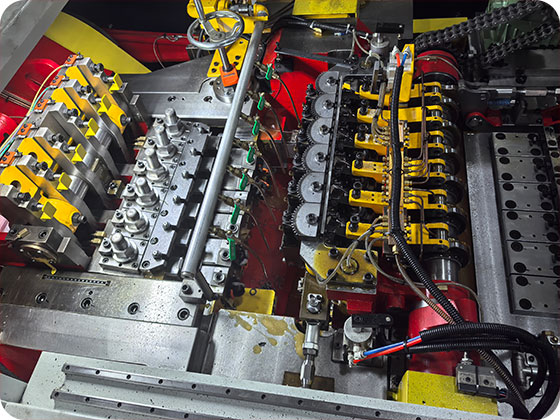

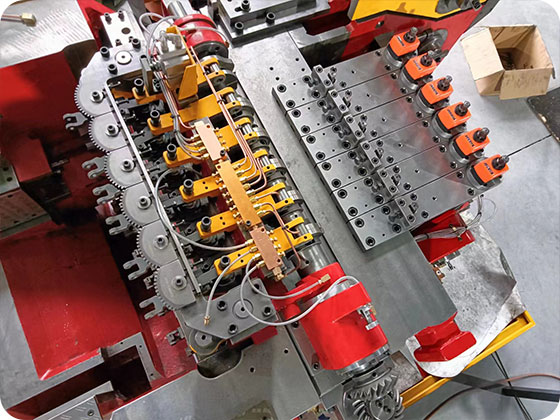

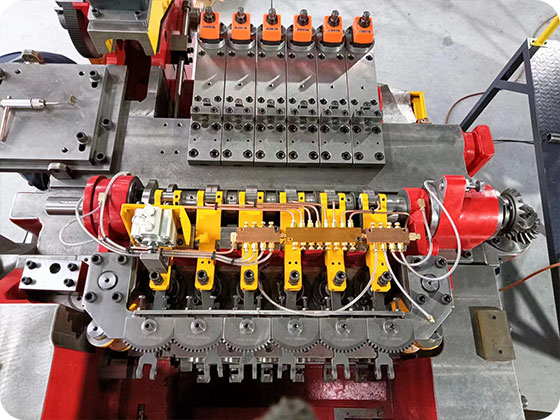

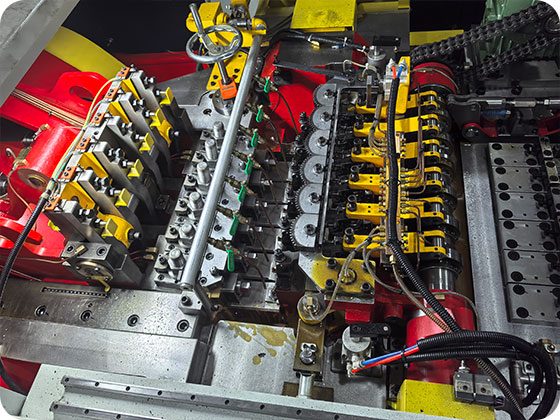

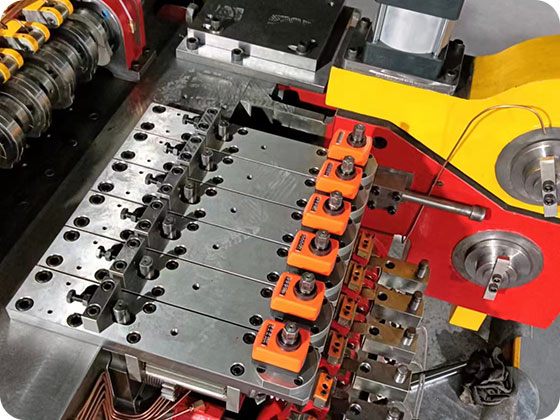

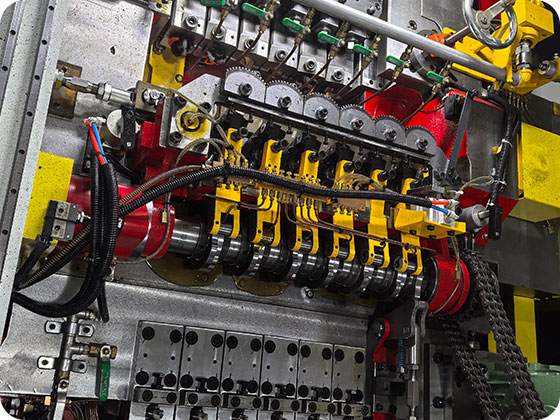

6 Station Fasteners Making Cold Former Machine is a kind of equipment used for metal processing, mainly used to form metal wire into various fasteners through multiple stamping. The following is a detailed introduction to the six-station cold heading machine:

The six-station cold heading machine is a multi-station cold heading forming machine that can complete multiple processes in one operation, reduce intermediate transfer and waiting time, and greatly improve production efficiency. It is suitable for large-scale production and high-output requirements, especially for the production of fasteners of various special shapes.

|

|

|

Six-station cold heading machines usually consist of multiple stations, each with a specific mold and pressure device. Its working principle is to gradually form metal wire into the required fasteners through a series of stamping operations. The specific steps include cutting, multiple stamping and forming, and finally forming a complete fastener.

|

|

|

| Model | Unit | XBP-66S | XBP-86S | XBP-106S | XBP-136L | XBP-136LL | XBP-166S | XBP-206L | XBP-256L |

| Forging station | NO. | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| Forging force | Kgs | 50,000 | 90,000 | 110,000 | 140,000 | 140,000 | 230,000 | 390,000 | 500,000 |

| Main motor | KW | 18.5 | 22 | 30 | 45 | 45 | 75 | 90 | 132 |

| Shank length of blank | mm | 15-75 | 15-80 | 15-110 | 20-160 | 20-200 | 25-160 | 25-200 | 50-250 |

| Max.cut-off dia | mm | Φ10 | Φ13 | Φ16 | Φ21 | Φ21 | Φ26 | Φ30 | Φ36 |

| Max.cut-off length | mm | 100 | 100 | 135 | 190 | 240 | 190 | 240 | 320 |

| Speed Range | pcs/min | 110-180 | 90-150 | 85-140 | 60-100 | 55-90 | 55-95 | 40-70 | 40-80 |

| Cut-off die.dia | mm | Φ32*45L | Φ42*60L | Φ52*75L | Φ58*80L | Φ58*80L | Φ74*105L | Φ94*130L | Φ109*150L |

| Punch die.dia | mm | Φ40*90L | Φ45*115L | Φ53*115L | Φ60*130L | Φ60*130L | Φ75*185L | Φ90*215L | Φ120*270L |

| Main die.dia | mm | Φ50* 120L | Φ60* 120L | Φ75* 135L | Φ94*190L | Φ94*240L | Φ108*200L | Φ125*240L | Φ148*300L |

| Main Slider Stroke | mm | 140 | 150 | 190 | 270 | 320 | 280 | 345 | 446 |

| P.K.O.Stroke | mm | 26 | 26 | 26 | 30 | 40 | 35 | 46 | 50 |

| K.O.Stroke | mm | 85 | 85 | 110 | 160 | 210 | 165 | 220 | 280 |

| Die pitch | mm | 64 | 80 | 94 | 110 | 110 | 129 | 140 | 160 |

| Applicable bolt dia | mm | 3-6 | 5-8 | 6-10 | 8-13 | 8-13 | 10-16 | 12-20 | 16-26 |

| Approx.weight | Ton | 16 | 20 | 24 | 38 | 42 | 56 | 80 | 150 |

| Max forging dia.on head | mm | Φ14 | Φ18 | Φ22 | Φ25 | Φ25 | Φ32 | Φ44 | Φ50 |

The technical parameters of the six-station cold heading machine include pressing force, shear diameter, etc. Different models of cold heading machines vary in these parameters. For example, the pressing force of the ZZYP series six-station screw cold heading machine ranges from 70,000 kgs to 210,000 kgs, and the shear diameter ranges from Ø11 mm to Ø18 mm. These machines are widely used in the production of fasteners such as bolts and nuts, and are suitable for many industries such as automobiles, construction, and machinery.

|

|

High efficiency: Multiple processes can be completed in one operation, reducing intermediate transfer and waiting time.

High precision: The dimensional accuracy and surface quality of parts can be guaranteed by precisely controlling the mold and pressure.

Material saving: The cold heading process itself has a high material utilization rate, further reducing waste generation.

Energy saving and environmental protection: Low energy consumption, reducing energy consumption and environmental pollution.

Versatility: It can be equipped with a variety of molds to adapt to the production of parts of different shapes and sizes.