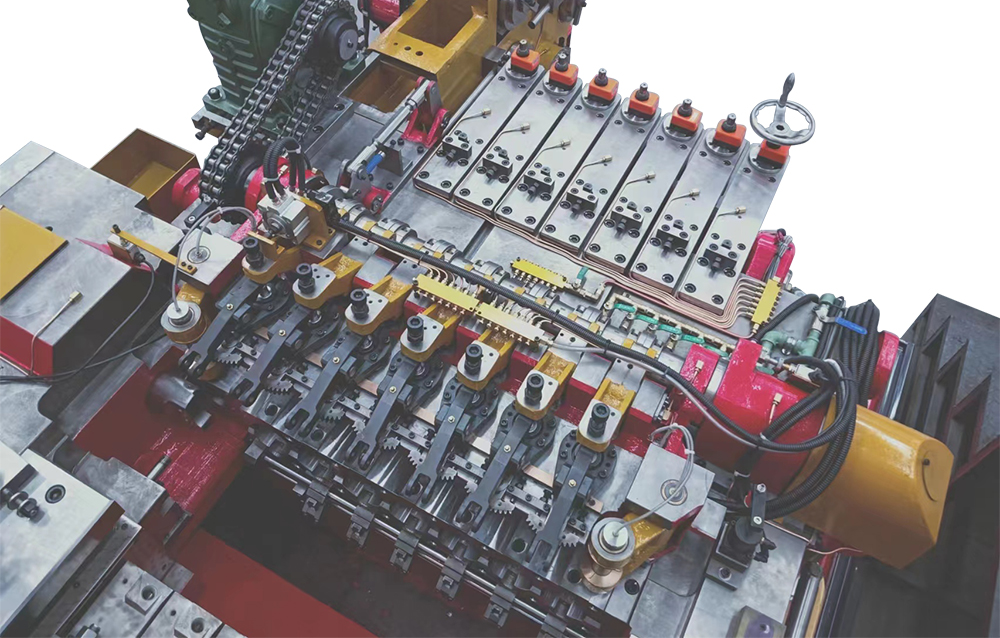

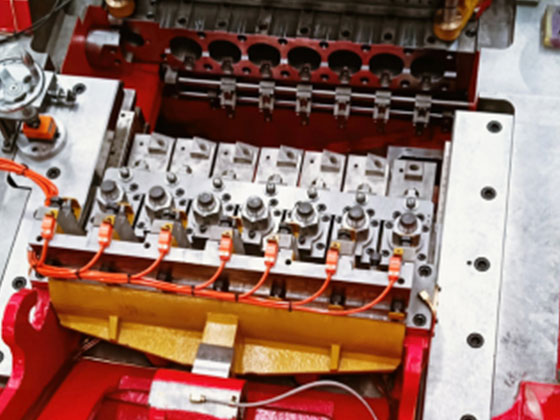

7 Station Nut Parts Cold Heading Press is mainly used for mass production of fasteners such as nuts and bolts. Cold heading machine is a kind of equipment specially used for mass production of fasteners such as nuts and bolts. It uses cold heading process to forge bars or wires into products of required shapes. 7-station cold heading machine means that it can process seven stations at the same time, which improves production efficiency and output.

The cold heading process is to apply pressure to the metal bar through the die at room temperature to make it plastically deform, so as to obtain the desired part shape. This process is suitable for the production of parts such as bolts, nuts, nails, rivets and steel balls. The materials can be copper, aluminum, carbon steel, alloy steel, stainless steel and titanium alloy. The 7-station cold heading machine can realize continuous, multi-station and automated production through the multi-station design, which improves production efficiency and product quality consistency.

|

|

|

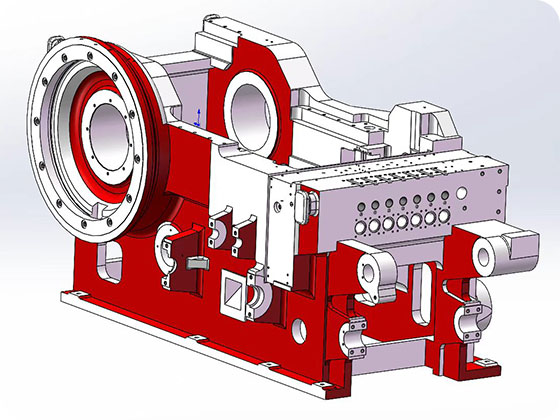

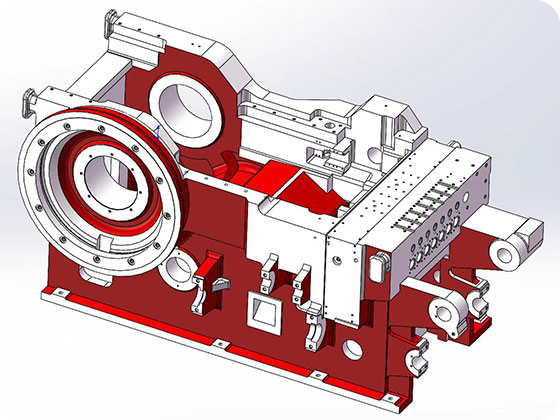

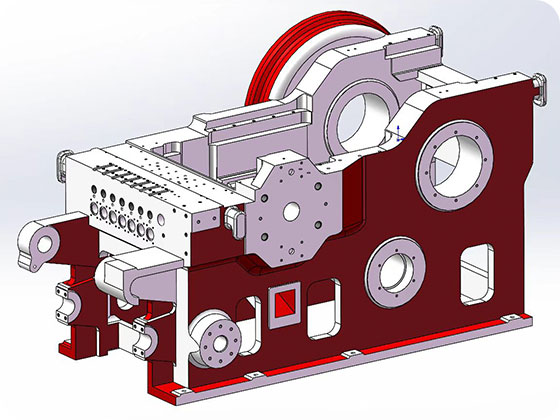

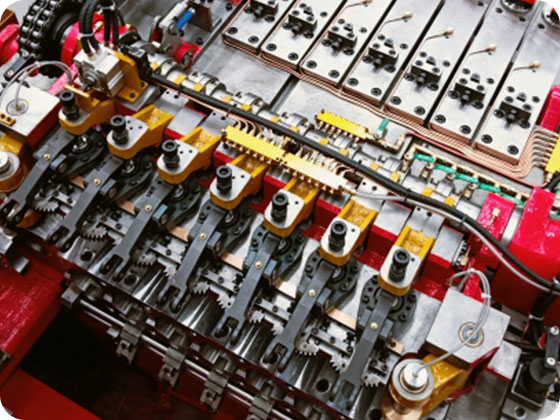

Multi-station design: The 7-station cold heading machine has multiple working positions, each of which has its specific function, such as cutting, upsetting, thread rolling, etc., which can realize automated production process and improve production efficiency.

Automated production: The equipment adopts an automated control system, which can realize the full automated production from cutting, upsetting to thread rolling, and is suitable for large-scale production of fasteners such as bolts and screws.

High precision and high efficiency: The 7-station cold heading machine adopts high-precision molds and transmission systems to ensure high precision of product size and shape, and high transmission efficiency, which is suitable for large-scale production needs.

Wide range of applications: Widely used in the fields of automobiles, motorcycles, mechanical foundation industries, etc., for the production of various standard fasteners, such as bolts, screws, nuts, etc.

|

|

|

| Model | Unit | XBP-87S | XBP-107S | XBP-137L | XBP-167L | XBP-207L |

| Forging station | NO. | 7 | 7 | 7 | 7 | 7 |

| Forging force | Kgs | 90,000 | 110,000 | 140,000 | 230,000 | 390,000 |

| Main motor | KW | 22 | 30 | 45 | 75 | 90 |

| Shank length of blank | mm | 15-80 | 15-110 | 20-160 | 25-160 | 25-200 |

| Max.cut-off dia | mm | Φ13 | Φ16 | Φ21 | Φ26 | Φ30 |

| Max.cut-off length | mm | 100 | 135 | 0190 | 0190 | 0240 |

| Speed Range | pcs/min | 75-140 | 70-130 | 60-90 | 55-90 | 40-70 |

| Cut-off die.dia | mm | Φ42*60L | Φ52*75L | Φ58*80L | Φ74*105L | Φ94*130L |

| Punch die.dia | mm | Φ45*115L | Φ53*115L | Φ60*130L | Φ75*185L | Φ90*215L |

| Main die.dia | mm | Φ60*120L | Φ75*135L | Φ94*190L | Φ108*200L | Φ125*240L |

| Main Slider Stroke | mm | 150 | 190 | 270 | 280 | 345 |

| P.K.O.Stroke | mm | 26 | 26 | 30 | 35 | 46 |

| K.O.Stroke | mm | 85 | 110 | 160 | 165 | 220 |

| Die pitch | mm | 80 | 94 | 110 | 129 | 140 |

| Applicable bolt dia | mm | 5-8 | 6-10 | 8-13 | 10-16 | 12-20 |

| Approx.weight | Ton | 22 | 28 | 42 | 62 | 95 |

| Max forging dia.on head | mm | Φ18 | Φ22 | Φ25 | Φ32 | Φ44 |

Cold heading machine is a device that uses the plastic deformation of metal under the action of external force to redistribute the metal volume through the die to form the required parts or blanks. The cold heading process is suitable for the production of standard fasteners such as bolts, screws, nuts, rivets, pins, etc.

Cold heading machines are widely used in the production of various fasteners, especially in large-scale production. Its high efficiency and high precision make it widely used in the fields of automobiles, motorcycles, and basic machinery industries.

|

|