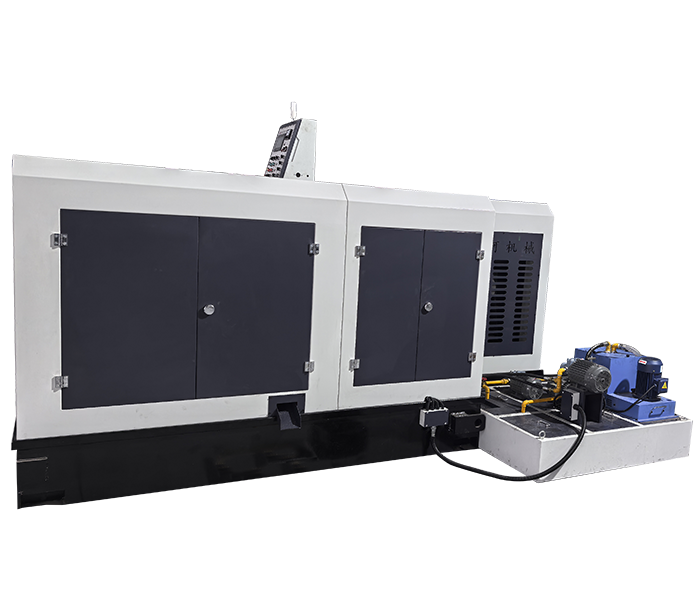

The 4 Station Bolt Automatic Cold Forging Machine is a device used to manufacture fasteners, especially suitable for producing bolts, nuts, nails, rivets and steel balls. It uses the cold heading process to sequentially complete the processes of cutting, heading, accumulation, forming, chamfering, thread rolling, diameter reduction and trimming on a dedicated cold heading machine to achieve continuous, multi-station and automated production.

|

|

|

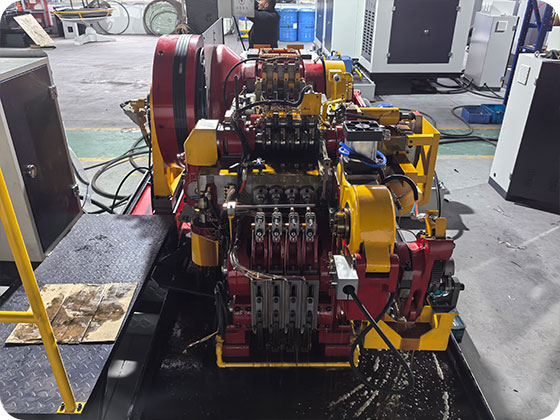

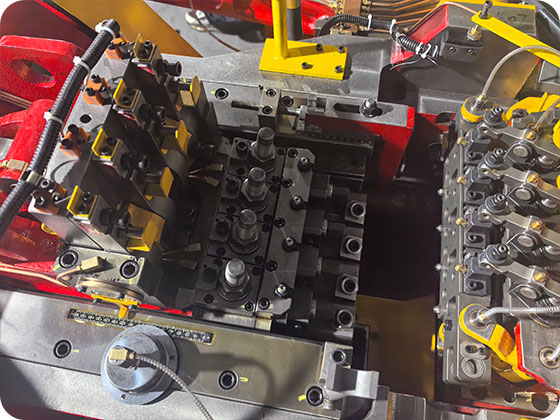

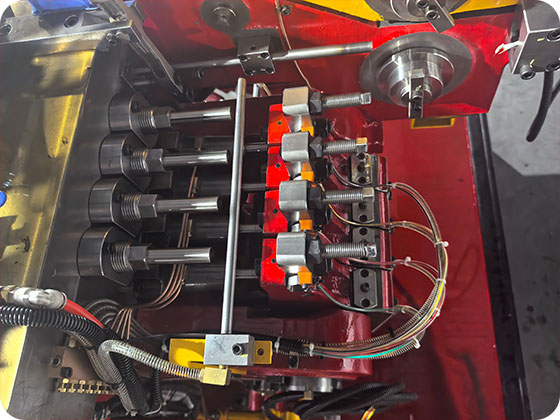

The main working principle of the four-station cold heading machine is to complete different processing steps in sequence through multiple stations. Each station has its specific function, such as cutting, heading, forming, etc. The machine adopts air clutch and inverter, which can realize multiple operation modes such as inching, single operation and continuous operation, ensuring mold safety and maximizing operation and debugging space. In addition, the four-station cold heading machine is usually equipped with advanced feeding system and clamping system to ensure accurate feeding and stable clamping.

|

|

|

| Model | Unit | XBF-64S | XBF-84S | XBF-84L | XBF-104S | XBF-104L | XBF-134L | XBF-134LL | XBF-164S |

| Forging station | NO. | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Forging force | Kgs | 40,000 | 60,000 | 80,000 | 80,000 | 80,000 | 120,000 | 120,000 | 210,000 |

| Main motor | KW | 15 | 22 | 22 | 30 | 30 | 37 | 37 | 55 |

| Shank length of blank | mm | 10-80 | 15-85 | 30-130 | 15-110 | 20-160 | 20-160 | 75-265 | 20-160 |

| Max.cut-off dia | mm | Φ8 | Φ10 | Φ10 | Φ12 | Φ12 | Φ15 | Φ15 | Φ20 |

| Max.cut-off length | mm | 105 | 110 | 155 | 135 | 190 | 190 | 285 | 195 |

| Speed Range | pcs/min | 140-210 | 120-180 | 90-140 | 90-140 | 80-135 | 75-110 | 45-70 | 70-100 |

| Cut-off die.dia | mm | Φ30*45L | Φ35*50L | Φ35*60L | Φ45*59L | Φ45*59L | Φ63*69L | Φ55*70L | Φ60*90L |

| Punch die.dia | mm | Φ40*90L | Φ45*115L | Φ45*115L | Φ53*115L | Φ53*115L | Φ60*130L | Φ60*229L | Φ75*185L |

| Main die.dia | mm | Φ50*110L | Φ60*120L | Φ60* 165L | Φ75*135L | Φ75*185L | Φ94*190L | Φ86*305L | Φ100*190L |

| Main Slider Stroke | mm | 136 | 140 | 230 | 190 | 262 | 270 | 380 | 260 |

| P.K.O.Stroke | mm | 15 | 18 | 26 | 20 | 30 | 40 | 45 | 30 |

| K.O.Stroke | mm | 90 | 100 | 140 | 110 | 160 | 170 | 280 | 170 |

| Die pitch | mm | 60 | 80 | 80 | 94 | 94 | 110 | 110 | 120 |

| Applicable bolt dia | mm | 3-6 | 5-8 | 5-8 | 6-10 | 6-10 | 8-13 | 8-13 | 10-16 |

| Approx.weight | Ton | 10 | 14 | 18 | 18 | 21 | 28 | 38 | 45 |

Four-station cold heading machines are widely used in the standard parts industry to produce various fasteners such as bolts, screws, rivets, nuts, etc. Due to its high efficiency and automation, four-station cold heading machines are used in many fields such as aviation, ships, machinery, rail transportation, automobiles, motorcycles, bicycles, etc., and are suitable for the production of various high-precision fasteners and special-shaped parts.

|

|

|