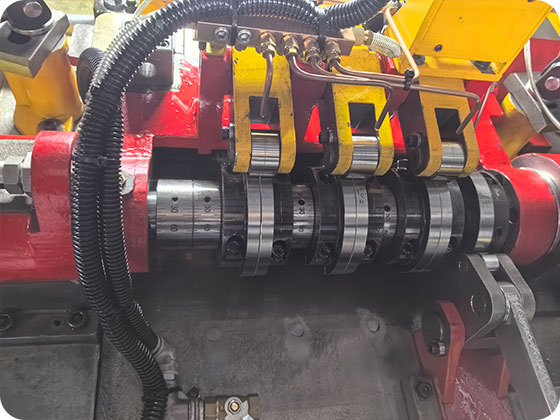

The 3 Station High Speed Bolt Cold Header Machine is a cold heading machine with three working positions, mainly used to produce ordinary internal and external hexagonal bolts and nuts. This equipment can process multiple parts at the same time, significantly improving production efficiency. The working principle of the three-station cold heading machine is to use a high-speed rotating mold to form the metal material into the required part shape at one time.

|

|

|

| Model | Unit | XBF-63S | XBF-83S | XBF-83L | XBF-103S | XBF-103L | XBF-133S | XBF-133L |

| Forging station | NO. | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| Forging force | Kgs | 35,000 | 60,000 | 60,000 | 80,000 | 80,000 | 115,000 | 115,000 |

| Main motor | KW | 11 | 18.5 | 18.5 | 22 | 22 | 30 | 30 |

| Shank length of blank | mm | 10-50 | 15 -80 | 25-110 | 15-70 | 30- 160 | 20- 100 | 70-210 |

| Max.cut-off dia | mm | Φ8 | Φ10 | Φ10 | Φ12 | Φ12 | Φ15 | Φ15 |

| Max.cut-off length | mm | 70 | 110 | 135 | 105 | 192 | 145 | 250 |

| Speed Range | pcs/min | 16-240 | 120-200 | 105- 180 | 120-200 | 80-140 | 95-160 | 60-100 |

| Cut-off die.dia | mm | Φ30*45L | Φ35*50L | Φ30*50L | Φ45*59L | Φ45*59L | Φ63*69L | Φ55*70L |

| Punch die.dia | mm | Φ40*90L | Φ45*120L | Φ45*140L | Φ53*115L | Φ53*112L | Φ60*130L | Φ60*179L |

| Main die.dia | mm | Φ50*85L | Φ60*125L | Φ60*150L | Φ75*108L | Φ75*200L | Φ86*135L | Φ86*265L |

| Main Slider Stroke | mm | 110 | 146 | 192 | 150 | 280 | 200 | 350 |

| P.K.O.Stroke | mm | 20 | 16 | 16 | 15 | 15 | 26 | 25 |

| K.O.Stroke | mm | 52 | 100 | 115 | 80 | 162 | 102 | 230 |

| Die pitch | mm | 60 | 78 | 70 | 90 | 90 | 98 | 110 |

| Applicable bolt dia | mm | 3-6 | 5-8 | 5-8 | 6-10 | 6-10 | 8-13 | 8-13 |

| Approx.weight | Ton | 8 | 10 | 14 | 15 | 20 | 20 | 31 |

The three-station cold heading machine is suitable for producing ordinary internal and external hexagonal bolts and nuts through the adjustment of molds and process parameters. These parts are usually used for general mechanical assembly, with large demand, but relatively low requirements for precision and strength. Due to its high efficiency and precision, the three-station cold heading machine has been widely used in fastener manufacturing.

|

|

|

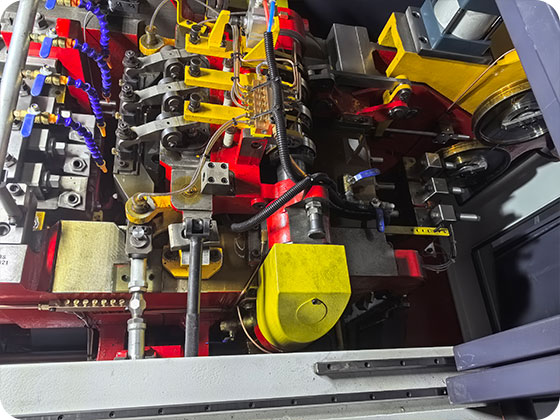

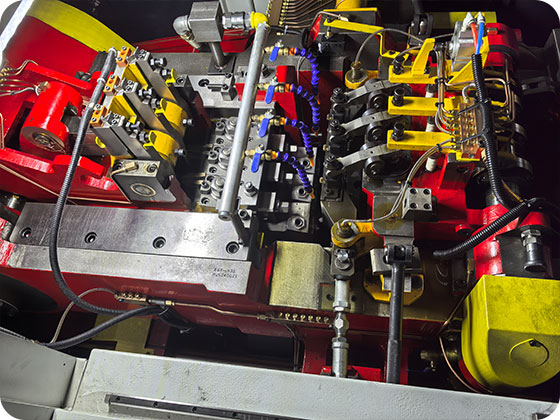

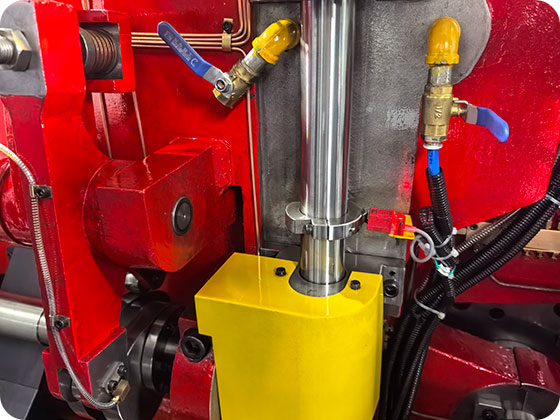

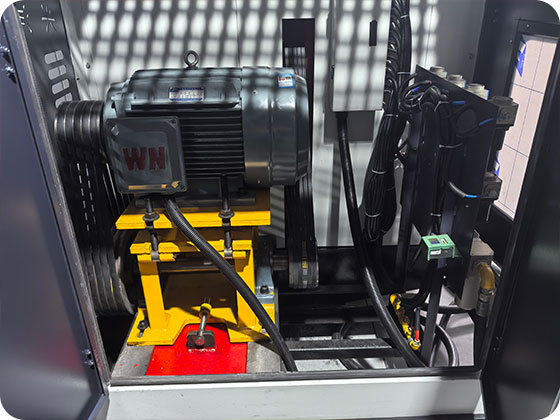

Three-station cold heading machines usually use opening and closing clamps to transfer workpieces, and the opening and closing time of each clamp can be adjusted individually. The main action mechanisms such as cutting, die ejection, and feeding are driven by connecting rods. In addition, the three-station cold heading machine also has a pneumatically controlled clutch and brake, which allows the main motor to start under no load, making it more convenient to debug the machine tool.

|

|

|